Introduction:

In recent years, 3D printing has emerged as a disruptive technology with immense potential in various industries, especially manufacturing. This revolutionary method of creating three-dimensional objects by adding successive layers of material has opened up new horizons in design, prototyping, and production. In this blog post, we will explore the exciting possibilities and benefits of 3D printing in the manufacturing sector, shedding light on its impact, applications, and future prospects.

- Understanding 3D Printing:

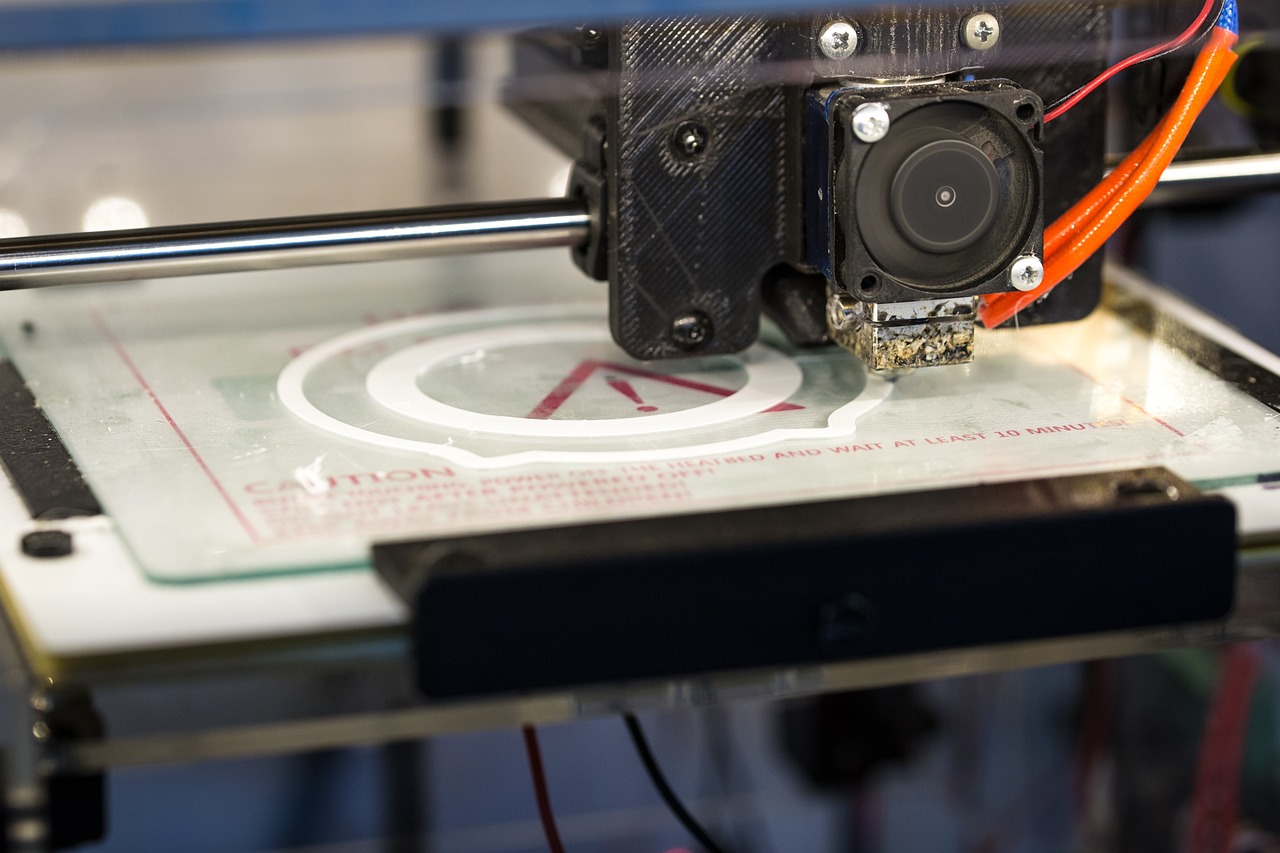

3D printing, also known as additive manufacturing, involves the creation of physical objects from a digital design by depositing layer upon layer of material. It offers several advantages over traditional manufacturing methods, such as injection molding or CNC machining. By eliminating the need for molds or complex tooling, 3D printing allows for rapid and cost-effective production of intricate and customized parts. This flexibility enables manufacturers to explore new design possibilities and iterate quickly, reducing time-to-market and promoting innovation. - Applications in Manufacturing:

The potential applications of 3D printing in manufacturing are vast and diverse. From aerospace and automotive industries to healthcare and consumer goods, 3D printing is revolutionizing the way products are made. In aerospace, 3D printing enables the production of lightweight and complex components, leading to fuel efficiency and improved performance. In healthcare, it has paved the way for personalized medical devices, implants, and prosthetics, tailored to individual patients’ needs. Additionally, 3D printing allows manufacturers to create on-demand spare parts, reducing inventory costs and minimizing downtime. - Benefits of 3D Printing in Manufacturing:

The adoption of 3D printing in manufacturing brings numerous benefits. Firstly, it offers design freedom, allowing manufacturers to create complex geometries and consolidate multiple parts into a single component, reducing assembly time and improving overall product performance. Secondly, 3D printing allows for on-demand production, eliminating the need for large-scale manufacturing and inventory storage. This not only saves costs but also reduces waste and promotes sustainability. Moreover, 3D printing enables the production of highly customized products, catering to individual customer preferences and requirements. - Challenges and Future Prospects:

While 3D printing has made significant strides in the manufacturing industry, it still faces some challenges. One of the main challenges is scalability. Although 3D printing excels in small-scale production and prototyping, it is yet to match the speed and cost-effectiveness of traditional mass production methods for large quantities. However, ongoing research and development efforts are focused on addressing these limitations and improving scalability.

Looking ahead, the future prospects of 3D printing in manufacturing are promising. As technology advances and materials become more advanced, 3D printing is expected to become more versatile, efficient, and cost-effective. Innovations such as multi-material printing, metal 3D printing, and continuous manufacturing are poised to revolutionize the manufacturing landscape further. With increased adoption and integration into existing production processes, 3D printing has the potential to redefine manufacturing as we know it.

Conclusion:

3D printing is transforming the manufacturing industry, offering unprecedented possibilities and benefits. From its design flexibility to personalized production and reduced costs, 3D printing is revolutionizing the way products are made. While there are still challenges to overcome, the future of 3D printing in manufacturing looks promising. As technology continues to evolve and research progresses, we can expect 3D printing to become an integral part of the manufacturing process, unlocking new levels of innovation, efficiency, and sustainability.